Revolutionising Workplace Safety with Industrial Ergonomics Software

Introduction: The Challenge of Musculoskeletal Disorders (MSDs) in the Workplace

Musculoskeletal disorders (MSDs) are a leading cause of workplace injuries, resulting in significant costs and productivity losses across industries. In the UK alone, an estimated 473,000 workers suffered from work-related MSDs in 2022/23, leading to the loss of approximately 6.6 million working days (Health and Safety Executive, 2023). In the United States, MSDs account for 30% of all workplace injuries, affecting muscles, tendons, and ligaments, often caused by repetitive tasks or awkward postures. The U.S. Bureau of Labor Statistics highlights that MSDs result in a median of 12 days lost per case, further emphasizing the urgent need for effective prevention strategies.

Work-related MSDs are strongly linked to physical, biological, and psychosocial workplace factors (Da Costa & Vieira, 2010). To mitigate these risks, organizations are increasingly turning to industrial ergonomics software powered by advanced technologies like AI-based motion capture. This innovative approach allows for more accurate and efficient ergonomic assessments, helping businesses reduce the incidence of MSDs and enhance productivity.

The Role of AI-Based Motion Capture in Industrial Ergonomics Software

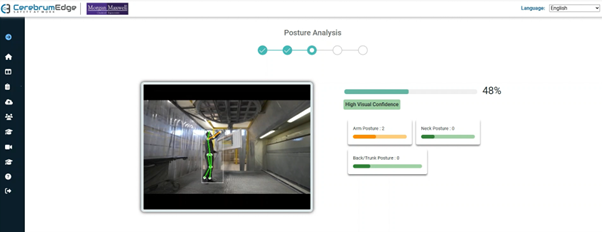

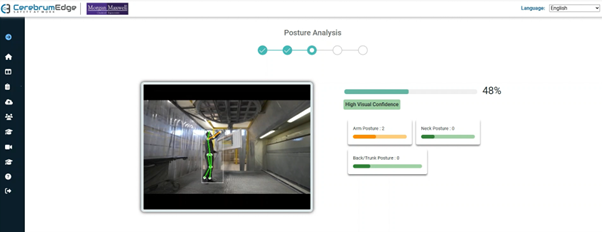

AI-driven motion capture technology is transforming the field of industrial ergonomics software by providing precise, real-time tracking of workers’ movements. Unlike traditional ergonomic assessments, which rely on subjective evaluations, AI-based systems use sensors and cameras to monitor posture, movements, and repetitive actions. This data offers a detailed view of how workers engage with their tasks, making it easier to identify potential risk factors for MSDs.

AI-based ergonomics software is able to detect movement patterns that may go unnoticed by human observers, especially in fast-paced environments. This precision reduces human error and bias, resulting in more reliable assessments. Furthermore, AI-driven motion capture systems can be scaled across an entire organization, enabling comprehensive data collection from multiple employees at once. This continuous monitoring allows for proactive intervention and ongoing improvements in workplace safety.

Camera vs. Accelerometer-Based AI Systems: A Comparative Analysis

AI-based motion capture systems for industrial ergonomics software generally fall into two categories: camera-based and accelerometer-based systems.

-

Camera-Based Systems: These systems offer non-invasive, real-time monitoring of workers’ movements. They are cost-effective and easy to deploy, making them ideal for large-scale assessments. However, their accuracy may be affected if workers’ limbs are obscured by objects or other body parts. In such cases, predictive models are used, but these models can introduce some uncertainty.

-

Accelerometer-Based Systems: These systems, which use sensors attached to the body, offer higher accuracy, particularly when camera visibility is limited. Accelerometers can capture data even when limbs are obstructed from the camera’s view, providing precise measurements of posture and movement. However, they are more expensive and require careful setup, making them less practical for large-scale, frequent assessments.

Both camera-based and accelerometer-based systems have unique advantages, and the choice of system often depends on the specific needs of the workplace. While accelerometer-based systems offer more accuracy, camera-based systems are more scalable and cost-effective, making them more accessible for many organizations.

Scaling Ergonomics Assessments with AI-Based Motion Capture

AI-based motion capture technology significantly increases the efficiency and scalability of ergonomic assessments. Traditional methods are time-consuming and resource-intensive, often requiring manual data collection and multiple site visits. In contrast, AI-powered industrial ergonomics software can quickly gather data from numerous employees, assessing ergonomic risks across various departments and roles simultaneously.

By automating the data collection process, AI-based systems free up ergonomics and safety professionals to focus on analyzing results and implementing effective interventions. Additionally, these systems can be integrated with existing workplace software, such as HR and safety management tools, creating a seamless flow of data and improving the overall effectiveness of ergonomic interventions.

The Importance of Expert Guidance in Ergonomic Assessments

While AI-based industrial ergonomics software offers impressive advantages in terms of data collection and analysis, it cannot replace the need for expert ergonomists. Ergonomics professionals bring a wealth of knowledge to the table, considering not just physical posture and movements but also a range of factors that influence worker health and safety.

Expert ergonomists assess various factors, including:

- Cognitive and Psychological Factors: How mental processes like attention and memory affect physical actions and risks.

- Environmental Conditions: The impact of factors like lighting, temperature, and noise on worker comfort and productivity.

- Workplace Culture and Social Dynamics: How team interactions and organizational policies influence safety and well-being.

- Human-Machine Interaction: Ensuring that tools, machines, and interfaces are ergonomically designed for safe and efficient use.

- Anthropometry: Considering individual differences in body size and shape to create more inclusive ergonomic solutions.

Combining the power of AI-driven industrial ergonomics software with the insights of expert ergonomists ensures that ergonomic assessments are comprehensive, effective, and tailored to the specific needs of each workplace.

Conclusion: The Future of Industrial Ergonomics Software

AI-based motion capture technology is revolutionizing industrial ergonomics software, offering organizations a powerful tool to enhance workplace safety, reduce MSDs, and boost productivity. While camera-based systems are cost-effective and scalable, accelerometer-based systems provide superior accuracy in certain environments. Both types of systems have their place in ergonomic assessments, and choosing the right solution depends on the unique requirements of each organization.

Ultimately, AI technology is most effective when paired with the expertise of ergonomics professionals. Together, they can create safer, more productive workplaces by addressing a wide range of ergonomic risks, from physical and cognitive factors to environmental and psychosocial elements. By investing in industrial ergonomics software powered by AI, organizations can reduce the burden of MSDs, improve worker well-being, and drive long-term productivity gains.

References

- Da Costa, B. R., & Vieira, E. R. (2010). Risk factors for work-related musculoskeletal disorders: A systematic review of recent longitudinal studies. American Journal of Industrial Medicine, 53(3), 285–323. https://doi.org/10.1002/ajim.20750

- Health and Safety Executive (2023). Work-related musculoskeletal disorders statistics (WRMSDs) in Great Britain, 2022/23. Available at: https://www.hse.gov.uk/statistics/assets/docs/msd.pdf (Accessed: 5 September 2024).

- U.S. Bureau of Labor Statistics (2020). Occupational injuries and illnesses resulting in musculoskeletal disorders (MSDs). Available at: https://www.bls.gov/iif/factsheets/msds.htm (Accessed: 5 September 2024).